HOT PRODUCTS

Why do wires and cables need to be twisted, and what are the advantages of twisted wires?

Let's open up the categories of twisted wires and their uses.

1. Ordinary stranded wire:

Aluminum stranded wire (LJ): Advantages: Lightweight conductor, good conductivity. Purpose: Used for distribution lines of overhead power lines with low stress.

Hard copper stranded wire (TJ): Advantages: superior electrical performance; Purpose: Overhead transmission lines.

Aluminum alloy stranded wire (LHAJ): Advantages: Tensile strength, conductivity 10% lower than aluminum stranded wire. Usage: glaciers, mountainous areas, hills and other places.

Aluminum clad steel stranded wire: Advantages: tensile strength. Purpose: Large span railway lines.

2. Combination stranded wire:

Steel cored aluminum stranded wire (LGJ): Advantages: tensile strength.

Usage: Overhead transmission lines, distribution lines, heavy ice areas, and large-span transmission lines.

Steel cored aluminum stranded wire: Advantages: prevents corrosion of the steel core and improves the service life of the wire.

Usage: Saltwater lakes, coastal areas, industrial and mining areas, and areas with severe corrosive atmospheres.

Aluminum clad steel core aluminum stranded wire: Advantages: prevents corrosion of the steel core and improves the service life of the wire. Reduce line loss. Reduced unit weight and increased wire span.

3. Special stranded wire:

Expanded diameter steel core aluminum stranded wire: Advantages: increases the outer diameter of the wire, saves non-ferrous metals, and reduces corona losses. Purpose: High voltage transmission and high-altitude transmission

Expanded hollow wire: Advantages: It has a larger outer diameter of the wire, reduces corona losses, and saves non-ferrous metals. Purpose: High voltage substation.

Vibration damping and gap type twisted wire: Advantages: Each twisted layer is separated, which can reduce vibration on its own. Usage: Areas with multiple storms.

Anti ice and snow stranded wire: Advantages: Anti ice and snow. Purpose: In areas with heavy ice.

Copper electric brush wire: Advantages: stable structure, good flexibility, made of bundle and compound twisting. Purpose: Wiring in motors.

Bare copper flexible stranded wire: Characteristics: It adopts various forms such as regular stranded wire, bundle stranded wire, non twisted wire, or twisted wire after bundle stranded wire according to regular stranded wire. Purpose: To connect motor and electrical equipment components.

Copper braided wire: Advantages: The wire is soft. Purpose: As a connecting cable for mobile electrical equipment, it is also used for connecting batteries in cars and tractors.

Aluminum coated steel core aluminum stranded wire: Features: galvanized steel wire is changed to aluminum coated steel wire. Increasing sex. Purpose: Used for power lines.

Weather resistant insulated overhead line: Characteristics: Adding insulation layer on the surface of LJ and LGJ stranded wires. Purpose: The route passes through forest areas and cities for use.

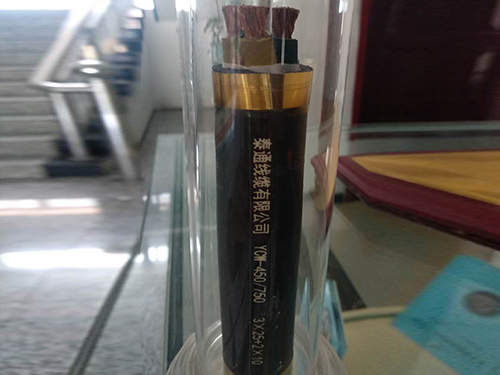

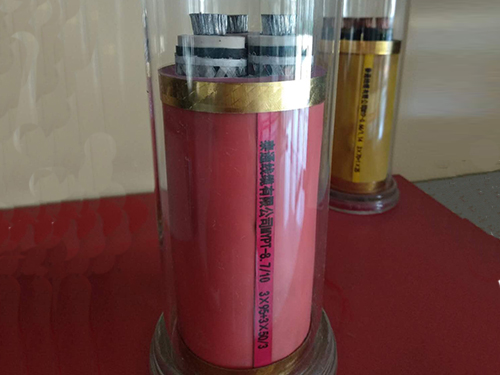

Conductive core: Characteristics: Most power cables are insulated with oil impregnated paper and plastic.

1. Hardwire core: used for marine cables, power cables, etc.

2. Flexible core: used for mining cables, rubber sheathed cables, etc.

3. Extra flexible cables: Use frequently moving wire and cable cores, as well as conductive wires and cables with specific requirements.

Now let's take a look at why it needs to be twisted and its advantages.

Why?

Using a single wire is not easy to bend and has poor flexibility, which brings difficulties to production, transportation, installation, laying, and use.

Due to the large cross-sectional area of a single wire, eddy current losses are high, which affects the transmission efficiency.

3. Purpose: To have a cross-section in terms of electrical performance; There is flexibility in mechanical properties.

advantage.

1. Good flexibility 2. Good stability 3. Good performance 4